Highlighting its commitment to manufacturing high quality products, Kee Safety has received CE markings for its range of BoxBolt® blind fixing solutions. Engineers and specifiers can have confidence that BoxBolt® products will deliver mechanical resistance, dimensional stability and durability.

Kee Safety commissioned a Notified Body to carry out an independent assessment of its Factory Production Control System and product performance. A third party confirmed that BoxBolt® products fulfil the requirements described in the European Assessment Document (EAD) 330001-00-0602.

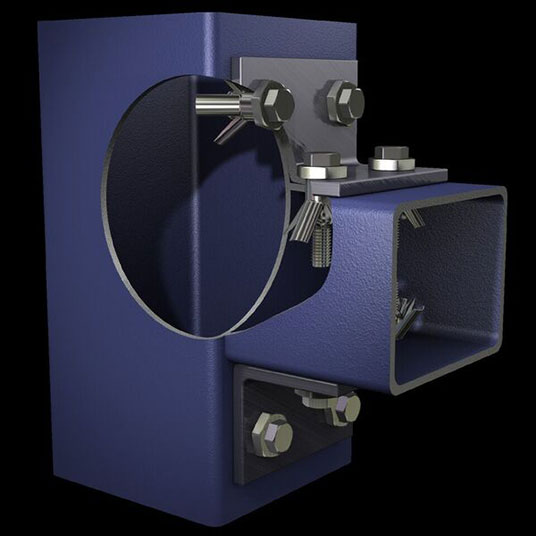

The BoxBolt® range — which includes M6, M8, M10, M12, M16 and M20 — is a fully tested and approved blind fixing solution for secondary steel connections. Suitable for connecting into rectangular, square and even circular hollow sections, or where access is restricted to one side only, BoxBolt® fixings feature a hexagon head design on the body to allow easy installation with a standard spanner.

The fixings deliver solutions for joining steel together without the need for on-site drilling or welding, providing much more flexibility than traditional methods. The system provides a guaranteed connection every time, without the need for on-site verification, as long as the installation guidelines are correctly followed.

BoxBolt® is available in three finishes, including zinc plated, hot dip galvanised and stainless steel. These finishes, combined with three available lengths, make it extremely flexible to suit its environment and application.

For more information, visit www.keesafety.co.uk